2023-12-21

1. Necessity of modification:

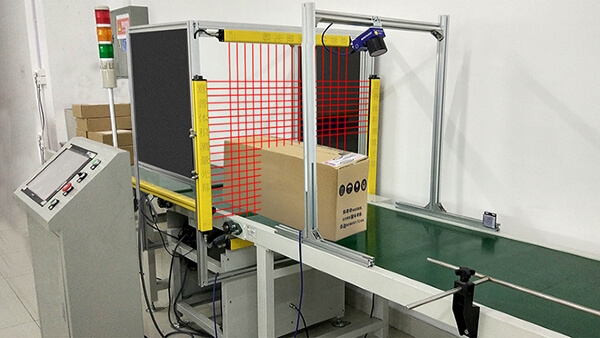

During the operation of the old punch, the worker needs to extend his arm into the punch area to operate, which increases the risk of injury. ESPE safety grating is a device that detects whether an object has entered a dangerous area through infrared or laser beams, and once the worker's arm enters the area, the grating will immediately stop the operation of the punch, thereby protecting the safety of the worker.

2.Implementation steps:

(1) Assessing risks: First of all, it is necessary to assess the safety risks in the operation of the old-fashioned punch. Understand the operation mode, working environment and potential risk factors of the punch press, and determine the specific installation location and quantity of the image grating.

(2) Purchase equipment: according to the actual needs, choose the appropriate safety grating equipment. Ensure that the equipment complies with the relevant national standards and safety requirements, can operate properly and is compatible with the press system.

(3) Installation and debugging: according to the installation manual provided by the equipment supplier, the ESA series safety grating is correctly installed around the punch. After the installation is completed, some necessary debugging and testing are carried out to ensure the sensitivity and accuracy of the grating.

(4) Train operators: Provide operators with training on how to properly operate and maintain safety grating, ensure that they can properly use the grating equipment and understand the relevant emergency management.

意普安全光栅保障工业安全,故障排查需准备手册、工具,遵循安全规程。排查步骤包括电源、指示灯、光束、校准、环境、连接及内部故障检测。定期维护、培训人员、记录故障是关键。

在现代化工业生产中,设备安全光栅作为保障人员与设备安全的核心装置,正被广泛应用于自动化生产线、机器人工作站、冲压机械等高危场景。其通过光电传感技术构建的"隐形防护网",不仅颠覆了传统机械屏障的局限性,更成为企业实现安全生产与效率提升的关键技术。意普安全光栅一、安全光栅的核心防护机制安全光栅由

意普测量光栅作为基于光学原理的传感器,在工业、科研等领域具有广泛应用。其高精度、高分辨率特点使其适用于微米甚至纳米级别的测量。未来,测量光栅有望实现更高精度、更快响应速度,并与其他技术结合,为各行业提供创新解决方案。