2023-11-09

1. Application cases of traditional safety grating:

Traditional safety grating is mainly used for the protection of industrial machinery, such as machine tools, laser cutting machines and so on. Through the safety grating installed around the machine, the machine will automatically stop running when it detects a person's approach, protecting the safety of the staff.

2. Application cases of multi-beam safety grating:

Multi-beam safety gratings are widely used in many fields. Taking autonomous driving as an example, the multi-beam safety grating can measure the location and distance of obstacles around the vehicle in real time to help the autonomous driving system make accurate decisions and obstacle avoidance operations.

In addition, the multi-beam safety grating can also be applied to the field of warehousing and logistics. In the logistics warehouse, by installing multi-beam safety grating near the shelves, it can realize the real-time monitoring of the stacking status of goods, as well as the safety management of personnel and items.

Compared with traditional safety gratings, multi-beam safety gratings have higher safety, accuracy and functionality. With the continuous development of technology, the application of multi-beam safety grating in various fields will be more and more extensive. However, options for different scenarios should be weighed according to specific needs and budgets to ensure maximum safety and benefit.

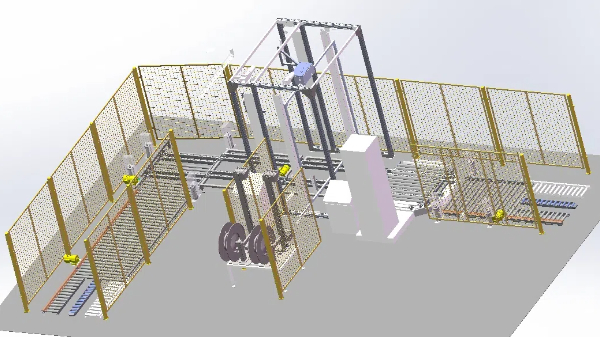

随着工业自动化的快速发展,机器和设备的运行速度也越来越快,使得人们在操作过程中面临更高的风险。为了确保工作人员的安全,安全光栅应运而生。安全光栅可以及时检测到人体或物体的存在,并快速采取措施停止机器的运行,以避免事故的发生。下面我们将详细探讨安全光栅的作用及其在工业领域中的应用。意普安全光栅案例图一

为了提升生产线的效率,预防工伤事故发生,深圳意普根据实际情况,为某知名电子厂提供“输送线安全整改方案”。该方案通过改进机械防护装置和优化作业流程,为企业实现了降本增效。应用案例:输送线安全整改方案项目背景在生产过程中,货物从进料口进入输送链,按顺序运行至指定位置进行加工,加工完成后,由输送链将货物运

安全光栅广泛应用在冲床行业、自动化机械、自动化焊接线、危险区域(有毒、高压、高温等)、剪切设备、机械传送搬运设备等领域上。