2023-09-19

First, safety interval

In general, the safety interval of the safety grating refers to the shortest interval between the light curtain and the working danger area - the cutting edge of the mold, that is, the interval required to stop the slider before reaching the dangerous border from the position of the hand to block the light curtain. The safety interval is one of the necessary conditions to ensure the protection function of the safety grating, and the safety interval must be calculated correctly! The calculation method should be determined according to the braking mode of the press.

Second, the position of the safety light curtain height

The height position of the safety curtain refers to the position of the light curtain of the safety grating relative to the upper and lower die of the machine tool. Under the condition of ensuring the safety interval, the last beam of the safety grating shall not be higher than the lower edge of the die, and the last beam of the safety grating shall not be lower than the upper edge of the die.

Third, the protection height

The protection height of the safety grating refers to the interval between the top beam of the light curtain and the next beam of the light axis, that is, the effective height of the light curtain. The protection height is the stroke of the machine tool slider plus the adjustment amount. The size of the protection height is related to the number of safety grating beams. If the number of safety grating beams is too small, the height of the light curtain will not be able to completely cover the dangerous area, and there is still the possibility of causing accidents. If it is too large, it will cause a waste of funds and inconvenience in use. Therefore, it is also very important to select the safety grating specification (beam number) according to the protection height.

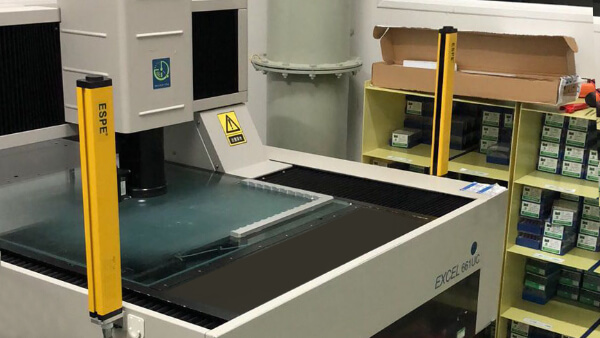

意普安全光栅是一种重要的安全设备,用于保护工人和设备。调整和校准光栅需要技巧,包括提前准备、参考标记、目测对准、使用工具、微调校准、测试验证和定期维护。遵循这些技巧可以快速准确调整光栅,确保最佳性能和安全。

安全光栅一般是用来做安全防护的,但是在选择安全光栅的时候,应该如何选择呢?意普安全光栅1、首先要明确需要购买安全光栅所需要达到的效果。是需要保护人体还是需要保护手臂或是保护手掌等。2、确定安全光栅所需要的电压,是220v还是24v电压,以免购买安全光栅后无法正常使用。3、确定分辨率。分辨率是指光栅可保护物体的

安全光栅是保障工业安全的关键设备,定期功能点检能确保其正常运行,预防潜在故障,保障人员安全,延长设备寿命,符合法规要求。点检方法包括外观检查、光束调试、功能测试和数据记录,有助于创造安全高效的生产环境。